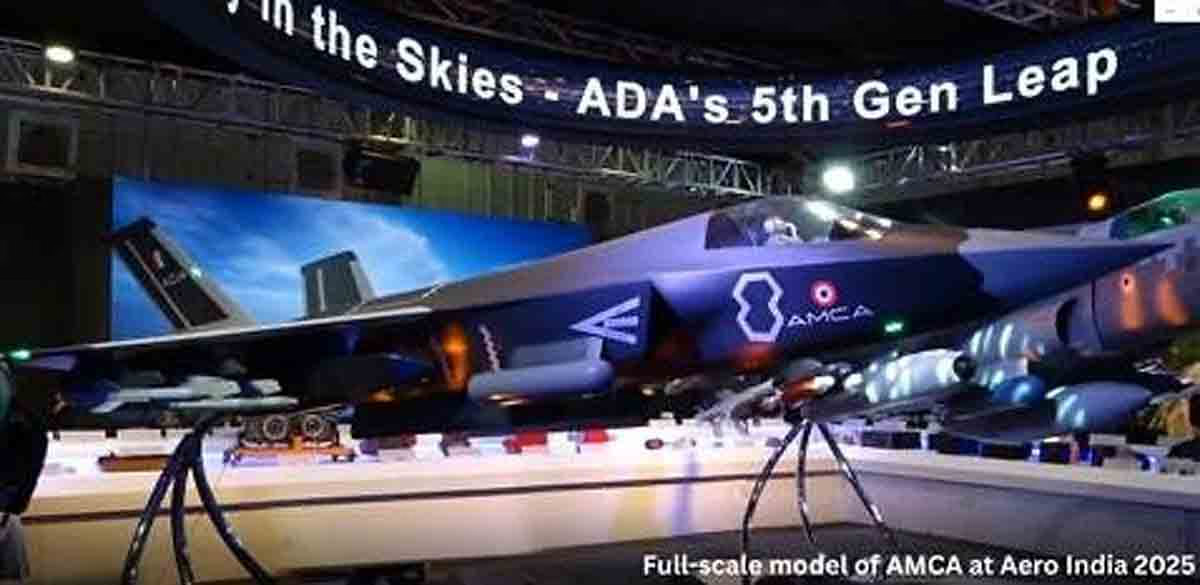

India, long striving for self-reliance in fighter jet engines, is set to reduce its dependence on nations like the US with its latest project. Recently, India inked a deal with French company Safran for the development of a 120kN thrust engine tailored for the Advanced Medium Combat Aircraft (AMCA). This partnership is pivotal, considering India's historical reliance on foreign engines for its fighter jets like Tejas, Sukhoi-30, and Rafale.

This ambitious ₹61,000 crore project, set to culminate in 10 years, aims to break the shackles of foreign reliance. It raises a crucial question: How transformative is this initiative for India's defense landscape?

Read More: Operation Sindhur - Overcoming Espionage Risks

The Dilemma: Dependence on Foreign Engines

Most engines for India's renowned fighter jets, such as the US's GE F404 for Tejas and Russia's AL-31FP for Sukhoi, are imported. Although efforts like the Kaveri Engine Project initiated in the 1980s aimed for self-reliance, they stumbled upon technological hurdles, failing to generate the desired 90-100kN thrust.

Source: aajtak

While the Kaveri engine program fell short and was sidelined from Tejas, its derivative version now powers unmanned aerial vehicles like Ghatak UCAV. Despite an investment of $400 million over 35 years, challenges such as mastering single crystal blade technology impeded progress.

These dependencies intensified issues, exemplified by GE F404’s delayed deliveries in 2021, stalling Tejas Mk1A production, and the Russia-Ukraine conflict hampering AL-31FP supply. The Safran project emerges as a beacon of hope to resolve these setbacks.

Read More: S-400 and Su-57 - A Combo to Subdue Pakistani Air Force

The Safran Initiative: A Glimpse into the Future

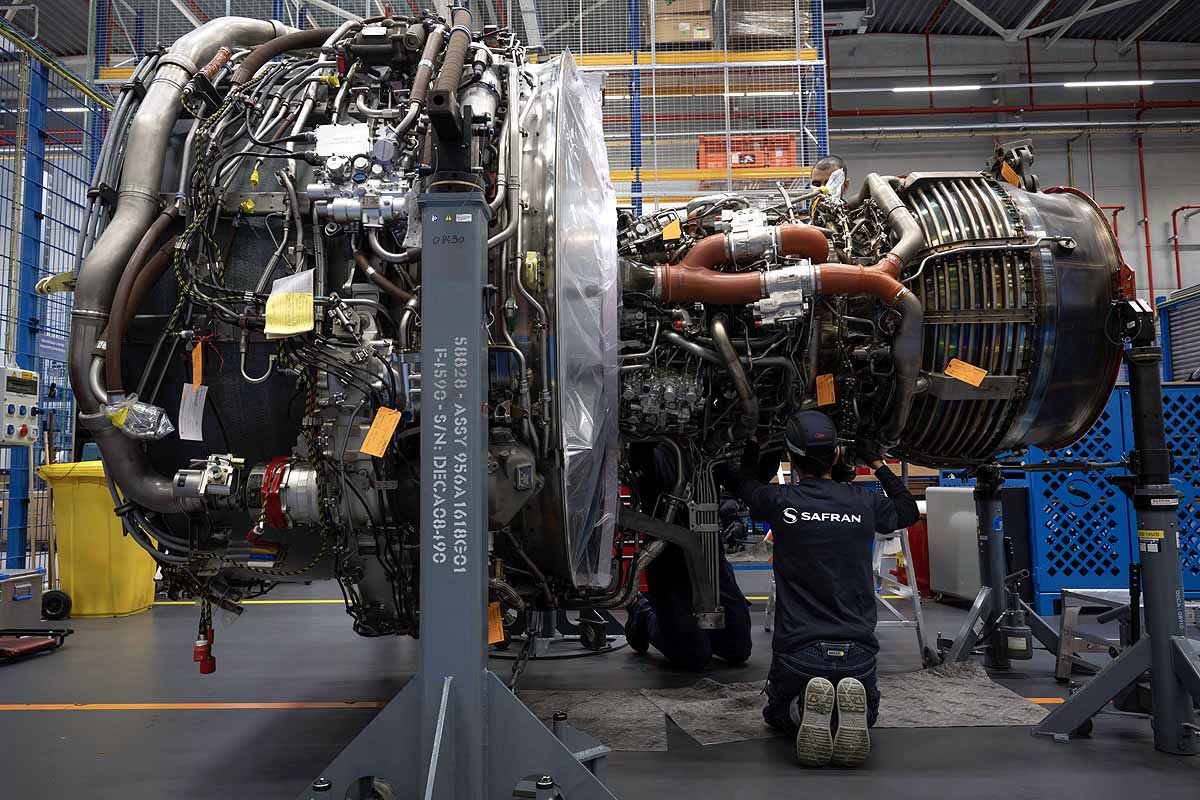

Announced by Defense Minister Rajnath Singh on August 22, 2025, the endeavor with Safran, known for the Rafale's M88 engines, comprises developing a 120kN thrust turbofan engine for AMCA Mk2. Valued at $7 billion (around ₹61,000 crore), the project promises comprehensive technology transfer, reinforcing India's defense manufacturing capabilities.

Source: aajtak

Key Highlights of the Agreement

A decade-long development timeline anticipating completion by 2035, with the engine integrated into AMCA.

Co-development with GTRE (a DRDO lab) aligning with Safran for design synergy.

Manufacturing relocated to India, featuring advancements like single crystal blades, thermal barrier coating, and an advanced combustor.

Enhanced export potential with indigenous engines lowering AMCA costs.

The Defense Ministry favored Safran's proposal for its promising offer of full technology transfer and integration with existing Indian projects like Kaveri. Despite competition from GE and Rolls-Royce, Safran stood out with prior collaborations, including a €1 billion proposal in 2016.

A Milestone for Self-reliant India

This project marks a revolutionary advancement for India's defense sector. Benefits unfold in layers...

Source: aajtak

End of Foreign Reliance:

With Kaveri's setbacks and reliance on GE, Safran, and Rolls-Royce, indigenous engines for platforms like AMCA and TEDBF will usher a new dawn. Defense Minister Singh affirms this is a substantial leap for 5th Generation fighters.

Acceleration for AMCA Program:

Set for readiness by 2035, AMCA will initially utilize GE F414 engines. However, the transition to Safran engines promises a wholly indigenous AMCA Mk2. With an investment of ₹15,000 crore, and five prototypes slated for development.

Technological Self-reliance:

Engines being the most intricate component, Safran's full tech transfer aids India in areas like single crystal blades and hot-end coating technologies. Kaveri's learned lessons bolstering Safran project support.

Economic and Export Growth:

Engines account for 40% of costs. Indigenous engines will facilitate cost-effective AMCA production, boosting exports and opening business avenues for HAL, GTRE, and MSMEs.

Read More: LCA Mk1A Fighter Jets First Delivery By October Despite Engine Delays

Strategic Security:

In conflicts or embargo scenarios, indigenous engines ensure an uninterrupted defense supply chain.

Challenges and the Road Ahead

The project faces hurdles: from funding constraints, akin to Kaveri’s $400 million expenditure over 35 years, to technological intricacies and a decade-long timeline. Yet, Safran's expertise with the M88 engine offers a safety net. The Kaveri derivative now powers drones like Ghatak UCAV. Future ambitions include Kaveri 2 (90-110kN) and Kaveri 3 (125kN), drawing inspiration from Safran. By 2025, Safran aims to inaugurate a maintenance hub in Hyderabad.