Defense Minister Rajnath Singh recently unveiled India's ambitious plans to accelerate the development of fifth-generation fighter jets and their engines, crafted right in India. This initiative will be executed in cooperation with the French aerospace company Safran.

This decision marks a monumental stride toward India’s self-reliance and a robust 'Make in India' ambition, serving as a powerful rebuttal to the U.S., which has delayed supplying engines for the Tejas amidst ongoing tariff disputes.

Also check out: How India's Fighter Jet Fleet is Set to Expand with 97 Tejas MK-1A

Fifth-Generation Fighter Jets: What Sets Them Apart?

The fifth-generation fighter jets stand at the pinnacle of modern combat aviation. Notable features include stealth technologies that evade enemy radar, supercruise capabilities allowing supersonic speeds without afterburners, sensor fusion for enhanced monitoring and targeting, internal weapons bays for greater stealth, and advanced avionics equipped with artificial intelligence.

India's Advanced Medium Combat Aircraft (AMCA) promises dominance in the air and deep strike capabilities, designed with a twin-engine model and 25-ton weight.

Also explore: India's Major Step in Self-Reliance with Stealth Fighter Jet Plan Approval

Source: aajtak

Partnering with Safran: Why It Matters?

India has strategically partnered with Safran, a leading French aerospace firm known for its M88 engines powering the Rafale jets in India’s air-force arsenal. Key aspects of this collaboration include the development of a 120-kilonewton engine for the AMCA’s Mk-2 variant, with complete technology transfer to India, fostering local production and enhancing India's intellectual property rights.

Powerful Engines: The 120 kN engine will boost the AMCA Mk-2, ranking among the world's most powerful engines.

Comprehensive ToT: Safran will provide full engine technology to India, empowering complete IP rights control.

Localized Production: Engines will be produced domestically, aligning with Make in India goals.

The investment in engine creation may span 10 years, evolving with DRDO and its Gas Turbine Research Establishment (GTRE).

Aerospace Ecosystem: Safran plans to develop a comprehensive engine manufacturing ecosystem in India.

Defense Minister Rajnath Singh emphasizes the strengthening of India's defense capabilities with the initiation of this significant project alongside Safran.

Also check out: French Fighter Jet Rafale Gives Tough Competition to American F-35

Source: aajtak

AMCA: India's Stealth Dream

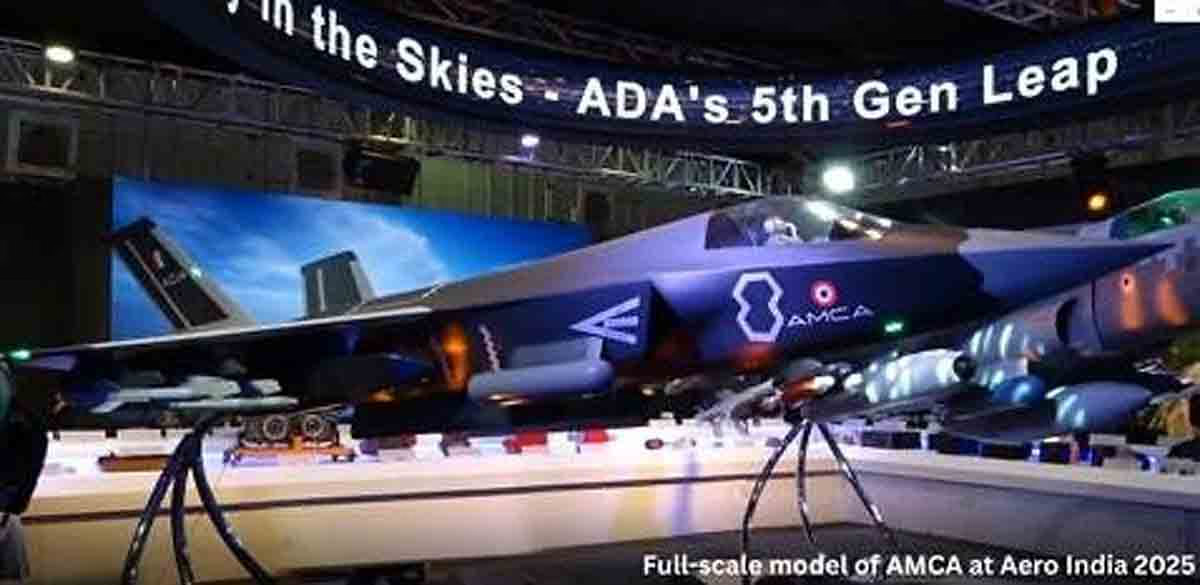

The AMCA represents India's first foray into a completely indigenous fifth-generation fighter jet, developed collaboratively with the Aeronautical Development Agency (ADA) and private enterprises.

Variants

Mk-1: Equipped with the GE-414 engine (98 kN) from the U.S.

Mk-2: Enhanced model featuring Safran’s 120 kN engine made in India.

Production Goal: By 2035, 7 squadrons (126 aircraft) will join the Indian Air Force.

Investment: Rs. 15,000 crore sanctioned for prototypes and design by the Cabinet Committee on Security last year.

Attributes: Stealth, supercruise, internal weaponry, and advanced sensors.

The AMCA will significantly boost India's air superiority and offer a strategic edge against regional adversaries like China and Pakistan.

Also explore: Ukraine’s Preparation for Major Strikes on Russia

Why Domestically Made Engines?

Historically, India has relied on foreign engines for its combat aircraft, such as the GE-F404 and GE-F414 engines from the U.S., Rafale’s M88 from Safran, and the AL-31 engine in the Su-30 MKI from Russia. However, delays and high maintenance costs of foreign engines present significant challenges for India.

Partnership with Safran will empower India with:

Self-Reliance: Reducing dependency on foreign imports.

Job Creation: Generating high-skilled employment opportunities.

Global Export Potential: Opening avenues for future engine exports.

Technology Advancement: Mastering cutting-edge technology fields and propulsion systems.

Source: aajtak

The Robust India-France Alliance

The defense relationship between India and France has always been formidable, showcased by various agreements like the Rafale deal, collaborative ventures between Safran and Hindustan Aeronautics Limited (HAL) on helicopter engines, and the inauguration of MRO centers in Hyderabad.

Strengthened in 2022 during meetings between Safran's CEO Olivier Andriès and Rajnath Singh, this alliance is a critical component of the Horizon 2047 roadmap, fortifying strategic ties between both nations.

Also see: Operation Sindoor: Indian Air Force’s Strategic Preparations

Tejas: A Symbol of Self-Reliance

Rajnath Singh emphasized Tejas as a testament to the excellence of India’s indigenous defense capabilities. Recent orders, including 97 aircraft amounting to Rs. 66,000 crore to HAL, exemplify commitment to domestic defense production.

Singh assured that despite challenges, India is steadfast in resolving them, achieving full competency in manufacturing combat aircraft.

Source: aajtak

Make in India and Its Global Role

Raj Nath Singh extended an invitation for global companies to invest in India. Highlighting the integral role of 'Make in India,' he emphasized its benefits not just for India but the world. Over the past decade, India has amplified its defense exports, marking a remarkable 686 crore INR (2013-14) to a projected 23,622 crore INR (2024-25) with a 50,000-crore INR target by 2029.

Collaborating with Safran aligns with India’s vision to emerge as a significant player in global defense markets, echoing PM Narendra Modi’s call for self-reliance in propulsion, semiconductor, and AI technologies.

Challenges and Future Prospects

Challenges: Engine manufacturing is an intricate, lengthy process, potentially over $7 billion USD (approx. 58,000 crore INR).

Opportunities: This project elevates India in aerospace technology leadership, bolstering Uttar Pradesh and Tamil Nadu’s defense industrial corridors.